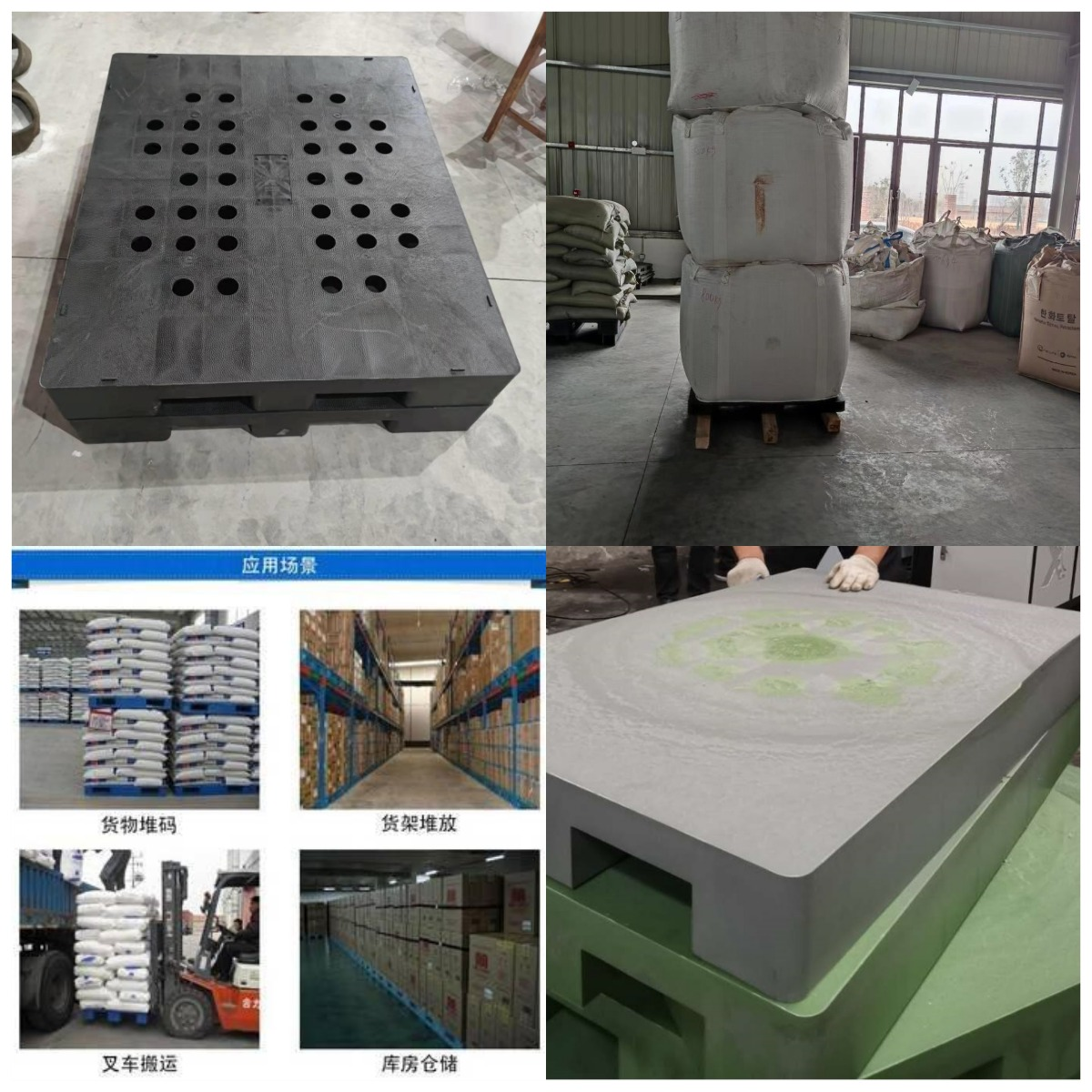

Single-station two-step waste plastic pallet molding equipment can mix pellets with hard waste plastics and plastic films. Fully automatic double station equipment is our company's patented product. Fully automatic two-step extrusion molding equipment: It is mainly used for various mixed waste plastic pellets or various used rigid waste plastics to be crushed (or cleaned, dried, dried) and added to the equipment to make produce the products we need.

Type | Frequency (pcs/min) | Pressure (T) | Output (KG/H) | Total Power (KW) | Products size | Screw diameter(mm) | Outside dimension (L*W*H) | Weight (Ton) |

GWJZD-1 | 1.5-2 | 315 | 100-150 | 45.63 | 300*300 | 90 | 6000*1460*3500 | 25 |

GWJZD-2 | 2-3 | 1500 | 350-450 | 250 | 1500*1300 | 65/130 | 10000*5400*6000 | 85 |

GWJZD-3 | 2-4 | 2000 | 400-550 | 330 | 1600*1300 | 75/180 | 12000*5800*6500 | 120 |

Hard materials include:

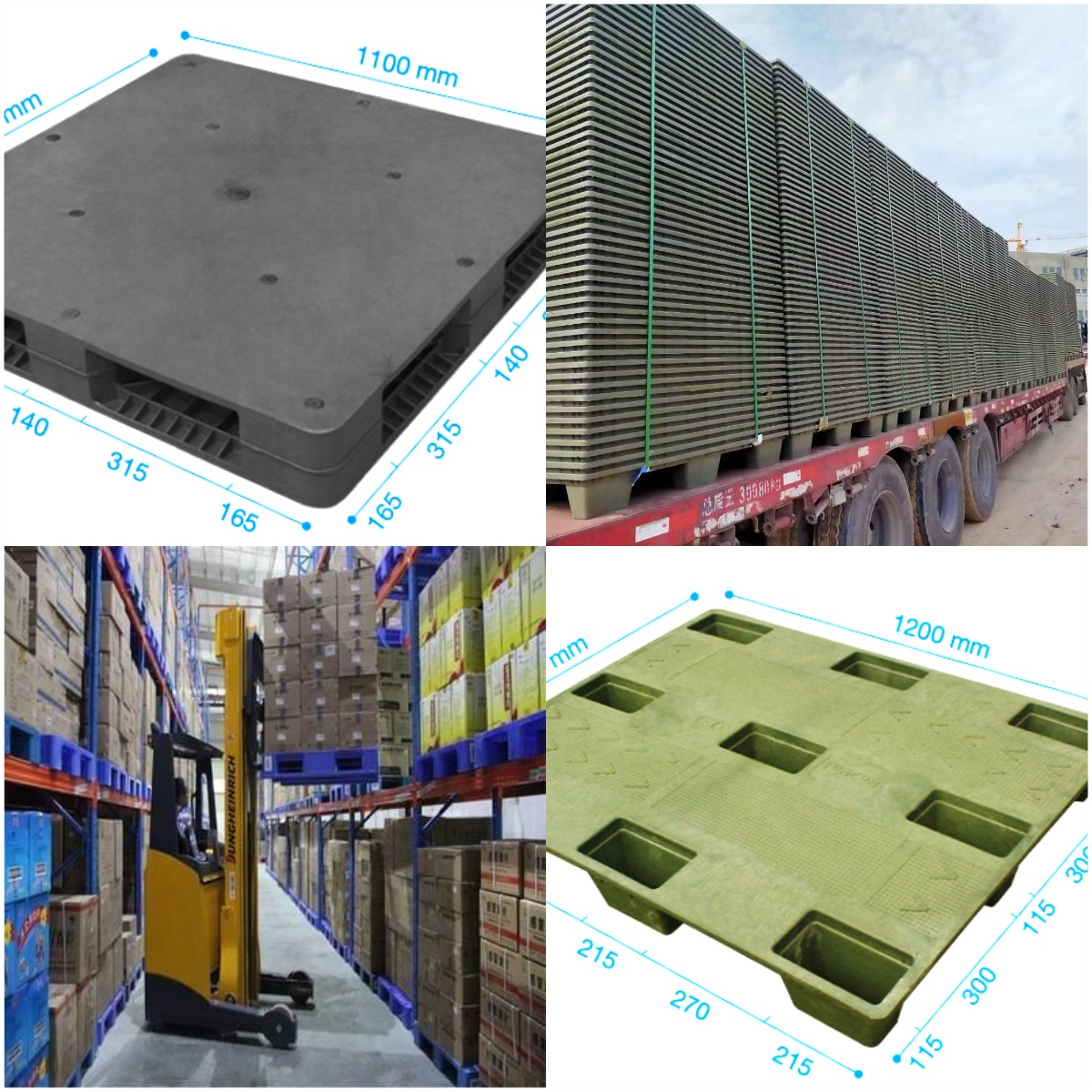

Clean: granulated material; iron factory material; industrial machine head material; home appliance material; pallet, etc.

Need to be cleaned: Materials used in life, baskets, toys, pots, etc.; Various barrels, bottles, etc.; Other materials.

The fully automatic two-step plastic pallet molding equipment adopts the co-rotating conical twin-screw specially designed by our company. The characteristics of the screw are smooth feeding, strong shearing force, and uniform dispersion. Due to the lengthened screw, the plasticization is good, and it is suitable for mixed waste plastics. Through precise design, it is ensured that the weight of each pallet is basically the same, and the error does not exceed 0.1 kg. The whole line is controlled by PLC and has a high degree of automation. One production line can be completed by only one person.

Get Plastic Recycling Machine from Guowang Eco for Different Applications.