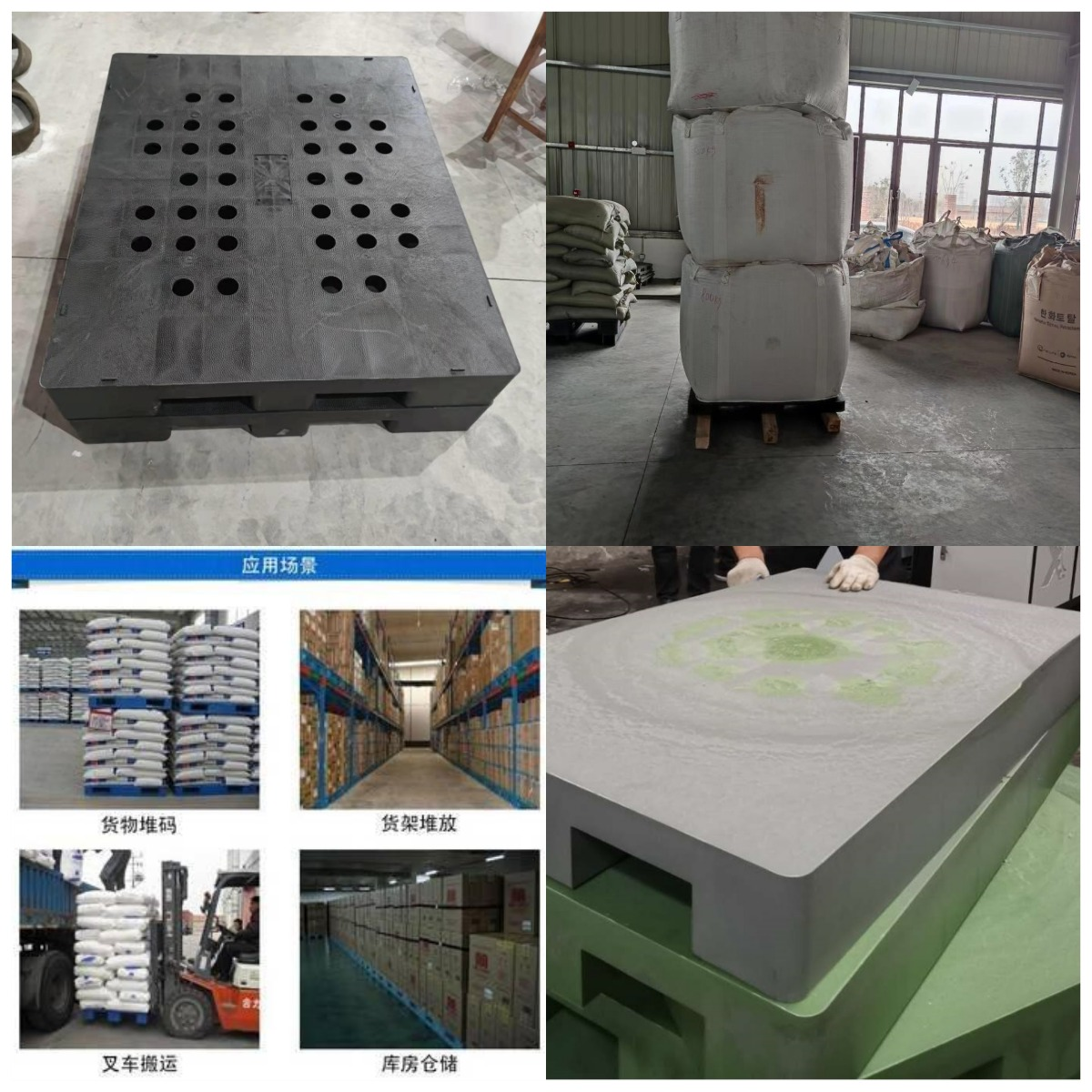

The difficult problem in the utilization of waste textiles (old clothes) is how to fully mix waste textiles and plastics. After multiple experiments and breakthroughs, GW ECO-TECH has developed specialized pre-treatment equipment for uniform mixing and good plasticization. Then, through the lifting device, forced feeding is carried out and enters the specialized extrusion plasticization equipment to achieve plasticization, remove impurities and other work. GW ECO-TECH can turn waste textile & cloth into usable pallets, manhole covers and other products. This equipment has a high degree of automation and requires fewer personnel. High efficiency, reducing costs.

The difficult problem in the utilization of waste textiles (old clothes) is how to fully mix waste textiles and plastics. After multiple experiments and breakthroughs, GW ECO-TECH has developed specialized pre-treatment equipment for uniform mixing and good plasticization. Then, through the lifting device, forced feeding is carried out and enters the specialized extrusion plasticization equipment to achieve plasticization, remove impurities and other work. GW ECO-TECH can turn waste textile & cloth into usable pallets, manhole covers and other products. This equipment has a high degree of automation and requires fewer personnel. High efficiency, reducing costs.

Textile waste is a growing problem worldwide, with millions of tons of discarded clothing and fabrics ending up in landfills each year. To address this issue, innovative technologies are being developed to enable the efficient recycling of textiles. One such technology is the One-Step Textile Cloth Waste Recycling Machine, which has been designed to simplify the recycling process by transforming textile waste into new raw materials in a single step. This cutting-edge fabric waste recycling machine has the potential to revolutionize the textile industry by reducing waste, conserving resources, and creating a circular economy for textiles. In this video, we will explore the features and benefits of the One-Step Textile Waste Fabric Recycling Machine and its potential impact on the textile industry and the environment.

Type | Frequency (pcs/min) | Pressure(T) | Output (KG/H) | Total Power (KW) | Diameter(mm) | Screw diameter(mm) | Products size | Outside dimension (L*W*H) | Weight (Ton) |

GWFFPD-1 | 2-3 | 1500 | 350-450 | 250 | 75 | 150 | 1500*1300 | 10000*5400*6000 | 85 |

GWFFPD-2 | 2.5-4 | 2000 | 450-550 | 400 | 90 | 165 | 1600*1400 | 14000*5500*7000 | 120 |

The One-Step waste cloth recycling machine is specially designed to process different materials like textiles, leather, wood, and plastic. It has a top-of-the-line control system that assists in managing all the processes and operations of the waste textile recycling machine. The system includes a water pump, pressure gauge, simple control circuit, and equipment feeder, thus making the cotton fabric recycling machine environmentally friendly and economically viable.

The high-quality parts used to build this textile waste recycling machine make it a durable product that will serve you for many years. This gives you an advantage over other brands that offer similar products but with subpar quality.

The garment waste recycling machine can be widely used in the paper, plastic, and textile recycling field. It is a new green environmental protection equipment for the textile, plastic, paper, and other waste materials recycling, which is used for recycling the waste fabric into raw material for the production of iron wire, etc. Fashion cotton fabric waste recycling machine is widely used for washing and recycling various cloth waste. It can greatly improve production safety, reduce labor intensity and save time in daily work at the same time, improving working conditions and the environment. As an innovative plastic recycling machine factory, our waste fabric recycling machine is equipped with advanced technology and has good performance. It also meets international standards and can be widely used in many countries around the world, so it has good prospects for export. Our garments waste cloth recycling machine is used for the recycling of all kinds of fabric waste, such as coat and bag slippers, cotton felt, and felt made of cloth, which can be turned into plastic tape and other raw materials. Cloth recycling machines can efficiently solve the problem of plastic waste in daily life.

According to incomplete statistics, more than 1 billion tons of used clothes are dumped into landfills worldwide every year, generating 2 million tons of carbon dioxide emissions every year. What is even more shocking is that by 2030, the impact of old clothes on climate warming will increase to 49%, and climate warming will make more and more polar bears homeless and even extinct. What can we do for polar bears in symbiosis on this blue planet?

A 2008 study conducted by the Bureau of International Recycling (BIR) at the University of Copenhagen in Sweden concluded that every kilogram of old clothing recycled can reduce carbon dioxide emissions by 3.6 kilograms. This also means that for every additional piece of old clothing recycled, we can slow down some more of the rate of global warming, and we have more hope of preserving a glacier for polar bears.

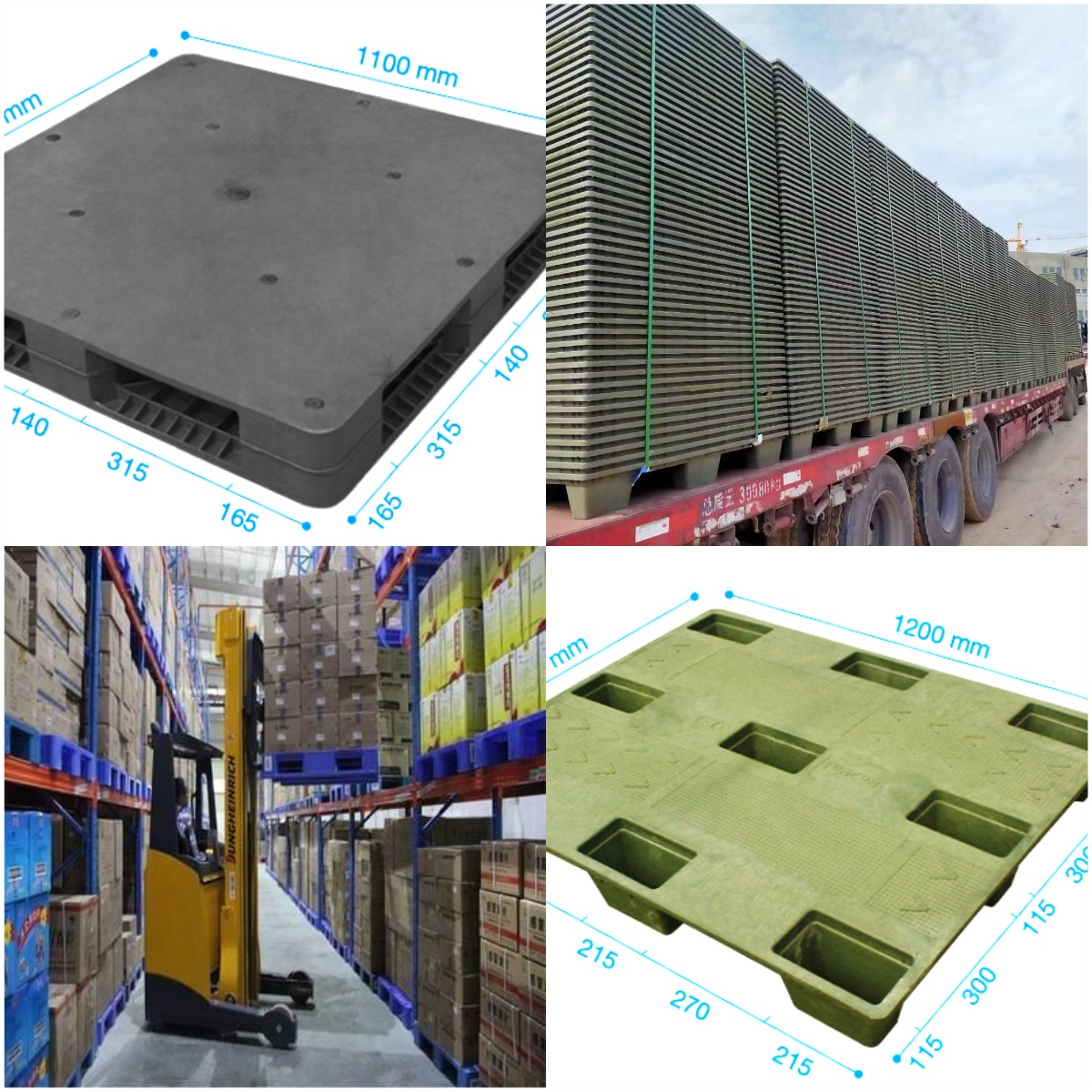

In view of this, our plastic recycling machine wholesale company has invested a lot of manpower and material resources in the research of waste textile recycling machines. A complete set of profile extrusion old cloth recycling machines has been developed, and the waste spinning and granulation are added to the one-step garments waste cloth recycling machine together with waste plastics and auxiliaries to directly make trays, manhole covers, flower pots, and other products.

Get Plastic Recycling Machine from Guowang Eco for Different Applications.